This unification can happen by automating existing workflows that run on manual, spreadsheet and legacy systems with a capable ERP system. An ERP enables enterprises to track operational data in real-time and present it in a contextualized, visualized manner relevant to their employees from the top floor to the shop floor.

The system eliminates manual processes and silo-based systems and provides relevant information to different functional departments such as sales, inventory, production, quality, engineering, accounting, shipping & logistics etc. for them to efficiently perform their tasks.

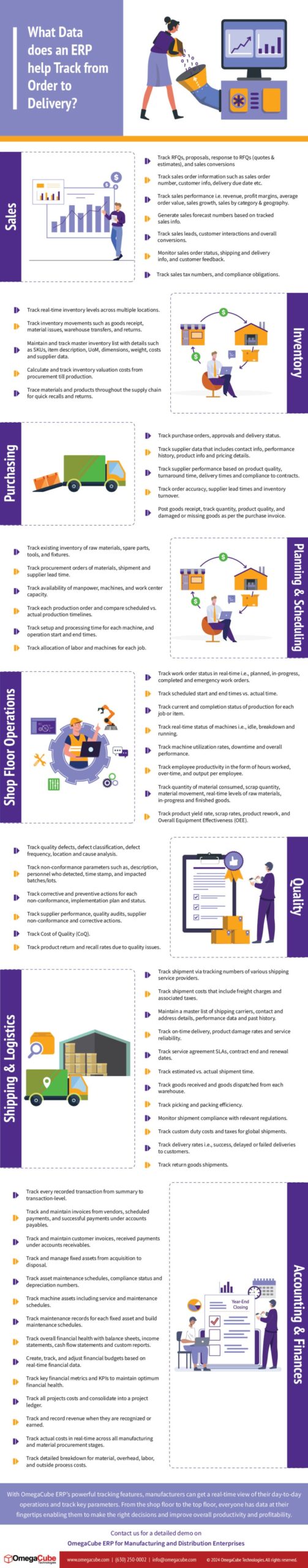

But what are the data types that an ERP records and tracks for each functional area/department? Let’s find out in the below infographic.

Conclusion

These are just some of the critical data that an ERP tracks for a manufacturing or distribution enterprise.

With OmegaCube ERP’s powerful tracking features for each functionality, manufacturers can get a real-time view of their day-to-day operations and track key parameters. From the shop floor to the top floor, everyone has data at their fingertips enabling them to make the right decisions and improve overall productivity and profitability.

Contact us for a in-depth demo on OmegaCube ERP’s data tracking capabilities.

5 Responses

Just exploring your services

Non ut quae sit expedita adipisicing minima amet facilis possimus et quae nihil

Omnis deserunt ullam exercitationem temporibus

Voluptas quam Nam quis omnis eveniet voluptatem Doloribus dolore doloremque facilis voluptatem Quis veniam labore accusamus et

Corporis dolorem exercitationem quia neque obcaecati quo sed autem dolor