In today’s competitive manufacturing environment, staying ahead of the competition isn’t just about producing high-quality products. It is about doing the same with efficiency, cost-effectiveness and agility to adapt to global chaos, volatile market conditions and supply chain. A capable manufacturing ERP software is all you need to provide that much-needed cushion and help you sail through. However, before taking the leap of faith, manufacturers often ask that critical question.

What’s the ROI of manufacturing ERP software?

Let’s find out.

Understanding ROI for a manufacturing ERP

An ERP’s Return on Investment (ROI) is measured by comparing the ERP implementation cost with various measurable benefits for the enterprise gained over time. Manufacturers commonly measure ROI through –

- Increased cost savings in various departments

- Improved productivity across the enterprise

- Increased Inventory efficiency

- Increased customer satisfaction

- Quick decision-making

Key manufacturing areas where an ERP delivers ROI

Inventory Optimization

Due to the lack of a proper inventory management system, manufacturers either overstock goods (leading to blocked capital) or understock goods (leading to emergency procurement, delays or lost sales). An ERP provides real-time information on inventory procurement and consumption, enabling them to take data-driven decisions and maintain optimum inventory levels.

Industry ROI – 20-35% reduction in inventory carrying costs.

ROI with OmegaCube ERP – One of our fabrication customers, Power Brace Manufacturing, reduced their inventory carrying costs from 3 million to 1 million.

Improved Production Efficiency

An ERP automates production workflows, enabling manufacturers to streamline production planning, scheduling, shop floor operations and control. Manufacturers can reduce downtime, scrap quantity and production costs with accurate BOMs, optimum resource utilization and real-time shop floor updates.

Industry ROI – 15-30% improvement in production throughput.

ROI with OmegaCube ERP – Our customers have achieved –

- 20-50% improvement in scheduling efficiency

- 2-4% material savings with OmegaCube ERP’s dynamic scheduling

- 90% decrease in scrap quantity

- 10% increase in on-time delivery

- ~100% increase in capacity utilization

Reduced Operational and Overhead Costs

With the automation of day-to-day and manual tasks such as order entry, invoicing, reporting, quotation, goods receiving, documentation, etc., manufacturers can reduce human errors, delays, and miscommunication to a great extent. This has a direct bearing on admin and operational costs.

Industry ROI – 10–20% decrease in administrative overhead.

ROI with OmegaCube ERP –

Our customers acheived,

- 30% decrease in paper usage

- Increases in process efficiency allowed for 300% business growth with no added administrative staff

- 80% reduction in human and manual errors

Enhanced Supply Chain Management

With global chaos, geopolitical uncertainty and market volatility, supply chain management becomes a big issue for manufacturers. A manufacturing ERP automates supply chain workflows and enables seamless communication and collaboration between suppliers, warehouses and the shop floor. This allows manufacturers to timely procure goods, leading to fewer delays, maintain optimum inventory, improve supplier relationships and prevent production delays.

ROI with OmegaCube ERP – Our customers observed 65-75% reduction in emergency inventory procurement with OmegaCube ERP’s supply chain management capabilities.

Improved Financial & Accounting Management

With an ERP, manufacturers can automate accounting and financial workflows to track costs in real-time, manage budgets and drive profitability. They can easily track account payables, receivables and general ledger entries for a clean book of accounts.

ROI with OmegaCube ERP –

Our customers achieved,

- 20% improvement in A/R processing efficiency

- 40% improvement in financial reporting efficiency

Increased Customer Satisfaction

With an ERP, manufacturers can provide real-time tracking of sales orders, accurately forecast delivery, provide better quality control and offer excellent service to customers. Happy customers mean repeat orders and referrals.

ROI Impact – Higher customer retention and increased revenue.

ROI with OmegaCube ERP – 1 week to 2 days improvement in customer response time

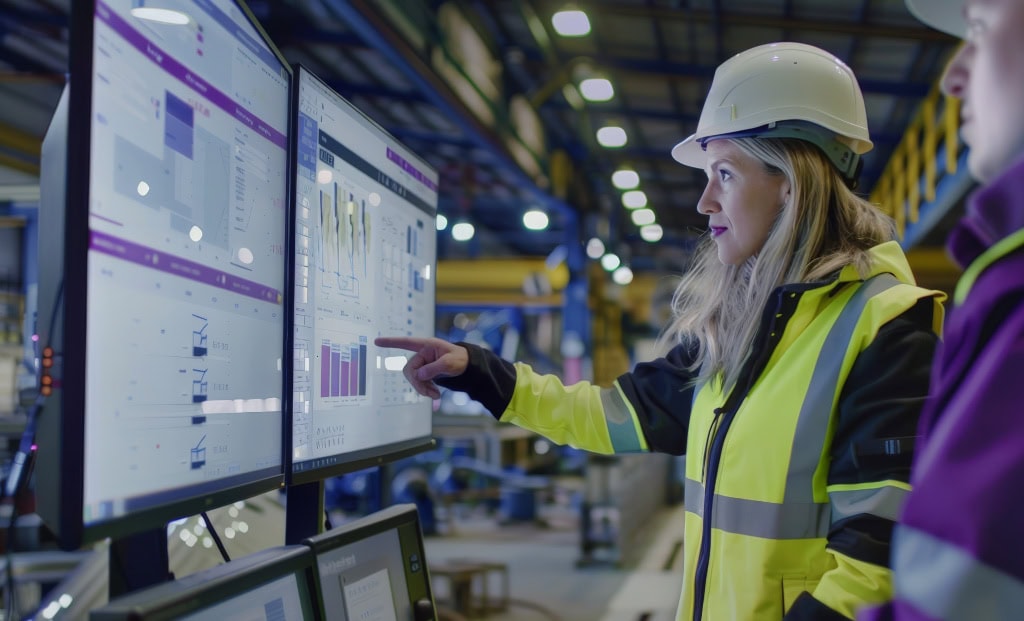

Real-Time Data for Smarter Decisions

An ERP’s real-time data tracking paves way for faster and smarter decisions, budgeting, and forecasting as data silos are eliminated and key decision-makers in the organization get access to real-time information displayed on custom dashboards and analytical reports.

ROI Impact – Faster response to market changes and better resource allocation.

How Long Does It Take for Manufacturers to See ROI of an ERP?

The typical time period for manufacturers to observe tangible ROI for their ERP is within 12 to 24 months post implementation. However, this depends on the size of the organization, scope of implementation and overall user adoption.

Conclusion

Implementing a manufacturing ERP is not just a technological upgrade. It is a strategic business decision that has long-term positive impact on your organization and its overall growth. The long term benefits such as cost savings, efficiency and agility outweigh the initial investment of an ERP. A ERP vendor who is capable of smoothly implementing an ERP using robust processes and expertise can help you get the maximum ROI benefit out of the ERP.

Are you ready to assess an ERP for your manufacturing enterprise?

Start with a needs analysis, compare solutions, and consider piloting with one department. The sooner you optimize, the sooner you save.

Take the first step by taking a quick demo of OmegaCube ERP. Contact our ERP experts to book a demo.

5 Responses

Just exploring your services

Non ut quae sit expedita adipisicing minima amet facilis possimus et quae nihil

Omnis deserunt ullam exercitationem temporibus

Voluptas quam Nam quis omnis eveniet voluptatem Doloribus dolore doloremque facilis voluptatem Quis veniam labore accusamus et

Corporis dolorem exercitationem quia neque obcaecati quo sed autem dolor