Material Requirements Planning (MRP) and Production Scheduling are amongst the most critical functions in an manufacturing environment. From spreadsheets and even paper to ERP/MRP systems, manufacturers are doing their every bit to efficiently manage production and scheduling.

However, the data communication happens only within the limits of these systems. Production personnel have little visibility into shop-floor operations and have to totally rely on data tracked through manual and paper-based systems by the shop-floor personnel. In the absence of Machine Monitoring and MES systems, a slight miscommunication or mis-representation of data can literally stop production and lead to wastage of materials, personnel and machine time; overall delay in production.

Therefore, it is very critical to completely integrate the shop floor with ERP/MRP systems. In our previous blogs, we had demonstrated how an integrated ERP & machine monitoring system enables manufacturers to have an increased control over shop-floor operations and continuous production & operational visibility.

So how does it all work?

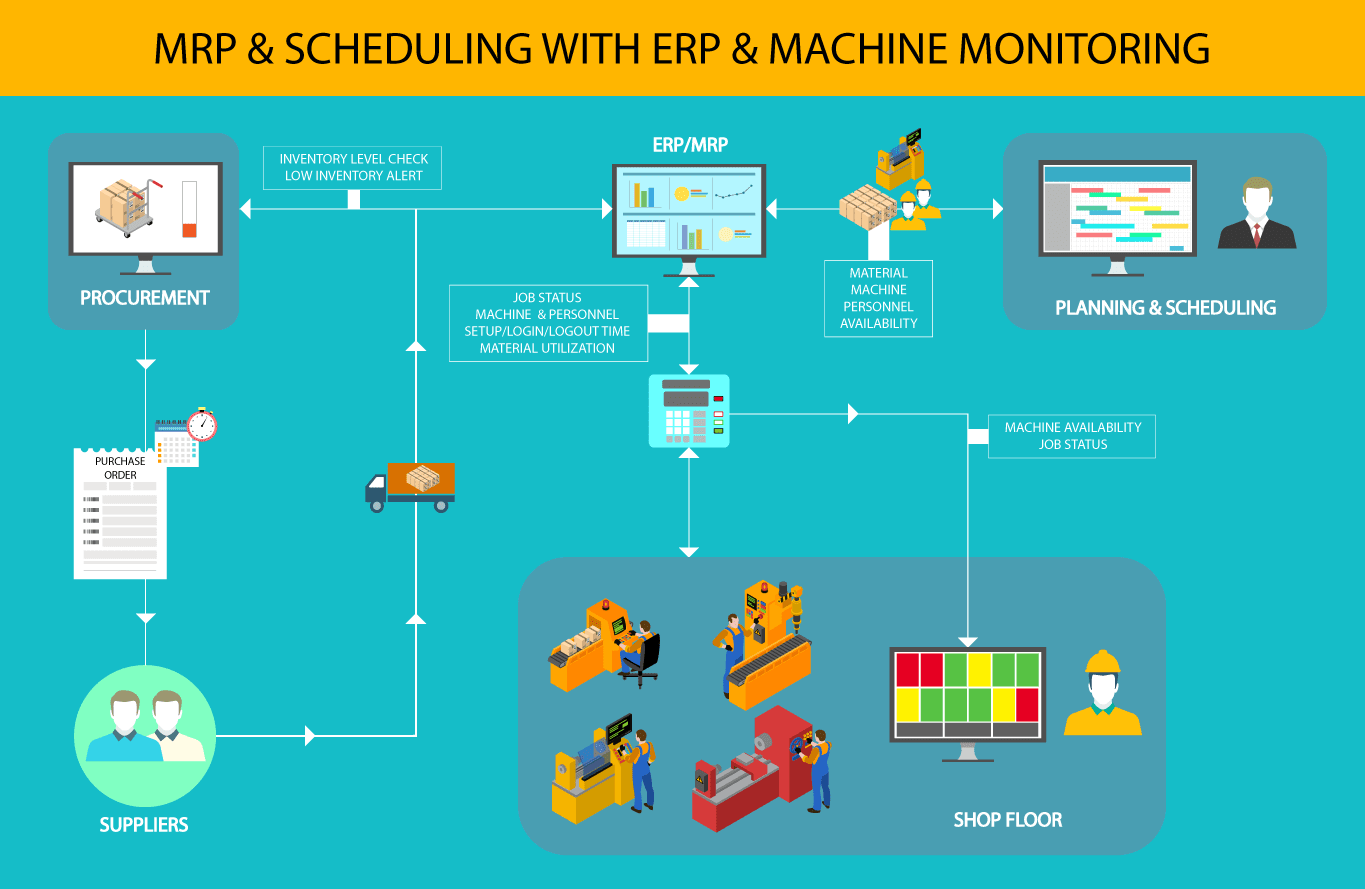

A manufacturer derives the Master Production Schedule (MPS) and Material Requirements Planning (MRP) based on the planned sales, expected orders and production numbers for the entire calendar year. Based on this data, the capacity and operational plan is created, personnel and machines are allocated, and procurement of raw material inventory is initiated from suppliers well in advance.

The operational plan or schedule is more elaborate and specific. It allocates orders to specific machines and personnel and allots time for completion of each activity. The entire scheduling is divided and displayed in the form of daily, weekly, and monthly report to provide a clear picture to the shop-floor and production personnel. Though the schedule is based on actual/projected customer demand, overall sales plan, expected orders, customer service, it is constantly subject to change by ad-hoc/emergency orders, high-priority customer service, material, machine & personnel availability etc.

All incoming sales orders are recorded into the ERP. Based on these, Work Orders are created that contains the number of parts to be manufactured, expected time of delivery and other details. To ensure smooth production flow as per the plan, the ERP/MRP system uses the current Bill of Materials (BOM) data, available inventory and MPS data to determine material requirement for each order. If the available inventory is below the required value, the ERP/MRP system sends a expedite procurement request to the suppliers well in advance so that the product can be manufactured and ready for delivery within the deadline. The MRP system ensures that inventory is procured only as per the equated demand and supply plan, and avoid over-stocks. This keeps inventory procurement and storage costs in check.

The integrated system of Machine Monitoring and Manufacturing Execution System (MES) take these work orders to production phase. In this phase, the system constantly monitors production and details such as machine setup time, machine uptime, scrap generated, job cycle time, personnel login/logout time, machine idle time, material utilization per job, number of products manufactured etc. are relayed to the ERP/MRP system. If there is an instance of machine downtime, it is immediately responded to and the concerned job is re-directed to other machine based on availability.

The real-time monitoring of machines and constant data flow enables the manufacturer to arrive at accurate and dynamic scheduling of production. Production schedule can be adjusted based on various parameters such as order inflow, priority, machine availability/issues, inventory levels etc. The personnel know what jobs are running smoothly and will be completed on time, jobs that have run into issues and the relevant reasons. Scrap data generated from the machines help arrive at material utilization, wastage, and overall quality of products.

Machine data is readily available to shop floor personnel, plant supervisors, plant owners etc. enabling them to take informed decisions. Shop floor personnel can instantly respond to machine & production related issues. Plant supervisors can use data to tweak production schedules and freshly forecast new production numbers. Plant owners have an overall consolidated data that shows the overall health of the manufacturing unit and expected production within a specific timeline.

Conclusion

The integration between ERP/MRP, MES and Machine Monitoring systems ensure that Material Requirements Planning (MRP) and Production Scheduling are not based on assumptions, algorithms, or data written on spreadsheets/paper. It is based clearly on facts gathered by the system. The same system that determines the schedule, executes it, plans material availability, manages personnel, routes/re-routes jobs, oversees production, and provides performance reports to owners and personnel. At the same time, ensuring smooth production, reducing inventory and storage costs, increasing material/personnel/machine utilization and profitability for manufacturers.

Watch Video

MRP is the crucial part of manufacturing process and needs to be taken care of. This blog conveys its important and very well illustrated. Thank you for the blog

Thank you very much for your feedback on the blog!